Inspection: Detects and classifies typical welding defects, including pores, holes, splash, edge notches and end craters.

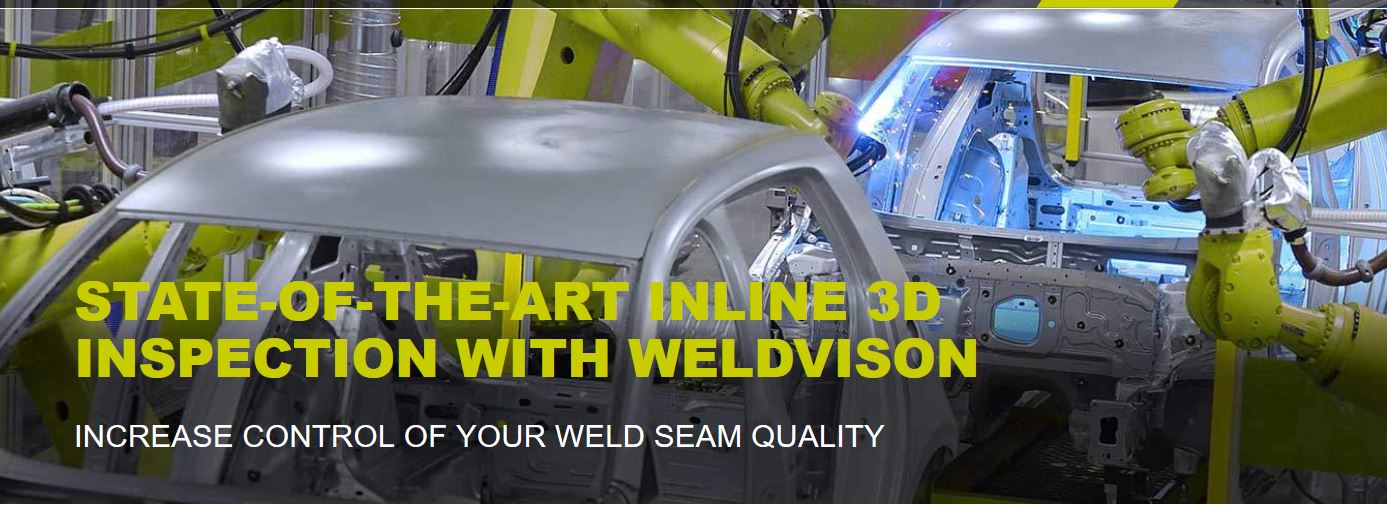

Guidance: WeldVision can be integrated into any manufacturing process and provides accurate robot guidance.

Measurement: Monitor the quality of your welded assembly by checking critical measurements with geometric precision.

15315450859

15315450859 0535-2162897

0535-2162897 sales@haizhichen.com

sales@haizhichen.com